Wood Engraving Blocks

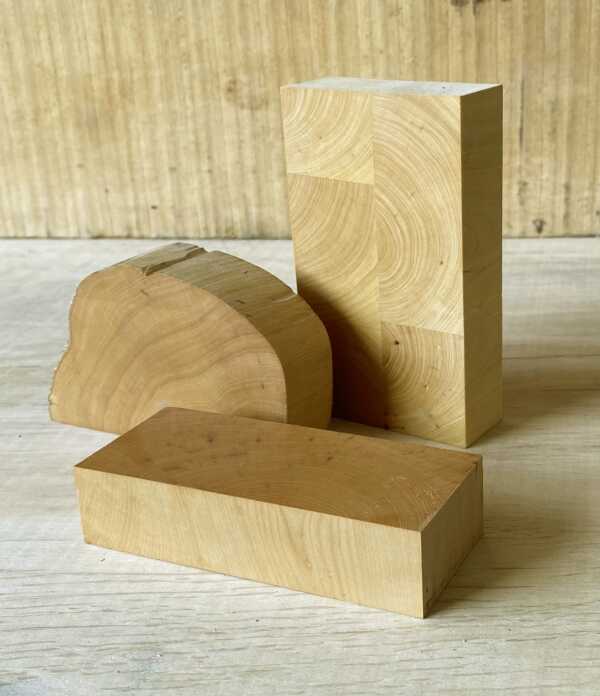

What defines wood engraving as a medium is the use of solid section gravers or burins on end grain wood. Surprisingly few woods have proved suitable over the centuries. Wood engraving blocks are always constructed on the end grain so that the tools cut across the annual rings, which have no directional differences, allowing cuts to be made evenly in any direction. Most importantly the wood needs to be even and dense throughout its end grain structure.

End grain engraving blocks are listed below and are priced per cm2. All woods are available as custom sizes and I also offer a range of ready made sizes in Lemon, Pearwood and Maple. Please refer to the section Care of Blocks to ensure that your blocks remain in good condition.

Made-to-order blocks: Blocks made to the exact size you require. I always make orders as promptly as possible, but please email me if you require your blocks by a certain date.

How to choose: If you are new to wood engraving, the best way to find out about the various woods is to buy a Practice Pack which will allow you to try out Boxwood, Lemonwood, Pearwood and Maple for yourself.

About Endgrain Blocks

Although engraving on end grain wood predates the work of Thomas Bewick (1753–1828), he is generally regarded as the father of wood engraving because of the unsurpassed mastery of his engravings. Bewick used end grain English Boxwood (sometimes Pearwood), still used by many modern wood engravers.

The wood engraver requires quite different qualities from the woods used by the woodcut printmaker. The latter will often exploit the texture and grain pattern found in a multitude of timbers used as a long or side grain surface, which are cut into with gouges and knives. The approach to engraving on end grain is quite different and necessitates both different tools and wood. Surface irregularity, often a virtue for the woodcutter, is anathema to the engraver. The blacks in a wood engraving will be dense and pure and the engraved work as fine and sharp as possible with no interference from wood grain whatsoever. For these reasons only woodcut and prepared from the end grain of a surprisingly small number of species will be suitable for wood engraving.

Such a wood will be very dense, yet not brittle or gritty, and exhibit even hardness across the annular growth rings so that the graver passes smoothly through the fibres. It will also need to be of a light colour so that the engraver can see the work progressing through a prepared darkened surface. Over time a small number of choice timbers have emerged as being the best for the technique.

Care of Blocks

End grain wood is susceptible to changes in temperature and humidity, requiring the engraver to take special care of the block both in use and in storage. Always store blocks on their edge, like books on a shelf with space between, and never flat. This is especially important with larger blocks and will greatly reduce the risk of dishing (warping in the centre).

In days of old, cold and dampness were the enemy, but we are now more likely to spoil our engraving blocks as a result of centrally heated rooms. The dramatic changes in room temperature brought about by central heating systems greatly increases the risk of blocks cracking and joints opening. This is because endgrain wood presents a large relative surface area of exposed fibres which react readily to changes in temperature and humidity.

In order to arrive at a realistic mean between excessive room temperature and the cold, damp cellar or garage, aim to store blocks in a room with the most constant, moderate temperature and as far away from a radiator as possible. Never leave a block on a windowsill or in direct sunlight. If using tungsten light bulbs beware of heat generated from a work lamp. Either switch off the lamp when not working or remove the block to a safe distance. However, now that LED lamps are the norm, this is not an issue since they do not generate much heat.